🗕️ Updated on: July 31, 2025

📘 Topic Relevance: JKSSB JE Civil, SSC JE, RRB JE, and other state-level exams

🔍 What are Hydraulic Machines?

Hydraulic machines are mechanical systems designed to either convert fluid energy (potential or kinetic) into mechanical energy or perform the reverse process. These machines operate on the principles of fluid dynamics and hydrostatics, utilizing the pressure, velocity, and flow characteristics of liquids to perform useful work. In civil engineering, they are crucial for tasks such as water transportation, power generation, irrigation, lifting operations, and energy storage. Their applications span across construction sites, municipal water systems, hydroelectric plants, and flood control mechanisms, making them indispensable in both urban and rural infrastructure projects.

🛠️ Classification of Hydraulic Machines

Hydraulic machines can be broadly classified into:

| Type | Function | Examples |

|---|---|---|

| Hydraulic Turbines | Convert hydraulic energy to mechanical energy | Pelton, Francis, Kaplan |

| Pumps | Convert mechanical energy to hydraulic energy | Centrifugal, Reciprocating |

| Hydraulic Press/Jack | Use Pascal’s Law to amplify force | Vehicle jacks, presses |

| Hydraulic Accumulator | Store hydraulic energy | Used in cranes, elevators |

🔧 1. Hydraulic Turbines (Energy Extractors)

Hydraulic turbines convert potential and kinetic energy of flowing or falling water into mechanical energy through the rotation of a runner or rotor. This mechanical energy is then often transformed into electrical energy using an alternator or generator in hydroelectric power stations. The process involves harnessing the energy of water at different heads (heights) and flow rates to rotate turbine blades, which are connected to a shaft. The design and type of turbine used depends on site-specific conditions like head, flow rate, and load requirements, ensuring optimal energy extraction from the hydraulic resource.

🔠 Working Principle:

A hydraulic turbine operates by directing high-pressure or high-velocity water onto the blades or buckets of a runner. The impact or reaction of the water flow causes the runner to spin, converting hydraulic energy into mechanical energy. This rotational motion is transferred through a shaft to drive a generator, converting mechanical energy into electrical energy. The design of the runner blades and the water flow configuration (impulse or reaction) determines the turbine’s efficiency and suitability for different head and discharge conditions. Proper alignment, flow regulation through nozzles or guide vanes, and energy dissipation mechanisms ensure smooth operation and maximum power output.

🥪 Types of Hydraulic Turbines (in detail):

| Turbine | Type | Water Head (m) | Specific Speed | Flow Direction | Example Application |

|---|---|---|---|---|---|

| Pelton | Impulse | >250 | Low | Tangential | Hilly hydro plants |

| Francis | Reaction | 30–250 | Medium | Mixed (radial & axial) | Multipurpose dams |

| Kaplan | Reaction | <30 | High | Axial | Run-of-the-river projects |

🌀 2. Pumps (Energy Givers)

A pump imparts energy to fluid, enabling it to overcome gravitational potential energy and frictional resistance in pipes or channels. The added energy increases the fluid’s pressure or velocity, allowing it to be lifted to higher elevations or transported across long distances. In civil engineering, pumps are critical for ensuring the delivery of water in municipal supply systems, draining flood-prone areas, and maintaining water circulation in treatment plants. The design and selection of a pump depend on factors such as required head, flow rate, fluid properties, and system layout. Efficient operation involves minimizing energy losses, avoiding cavitation, and ensuring proper priming and maintenance.

🥪 Main Types of Pumps:

A. Centrifugal Pumps:

- Convert rotational kinetic energy to increase fluid pressure.

- Operate at high speed and have continuous flow.

- Used in irrigation, water supply schemes, stormwater drainage.

- Components: Impeller, casing, suction pipe, delivery pipe.

B. Reciprocating Pumps:

- Use back-and-forth piston motion.

- Provide intermittent and pulsating flow.

- Used in dams, chemical plants, boiler feed.

- Types: Single acting, Double acting.

🧹 Pump Performance Terms:

- Manometric Head (Hm): Head against which pump works.

- Suction Head: Vertical height from fluid surface to pump center.

- Delivery Head: From pump center to outlet.

🏋️️ 3. Hydraulic Jack and Press

These devices utilize Pascal’s Law to amplify applied force. They’re vital in construction and mechanical lifting operations.

🔠 Principle:

If pressure is applied to a confined fluid, it is transmitted equally in all directions, allowing a small force to lift large loads.

🛠️ Applications in Civil Engineering:

- Lifting bridge components

- Rail track repair

- Heavy machinery alignment

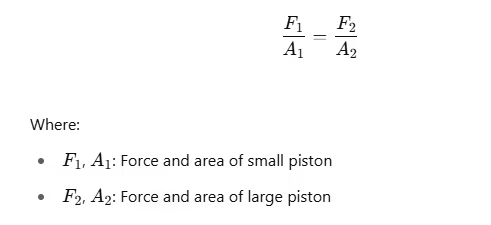

🥪 Key Formula:

📦 4. Hydraulic Accumulator

An accumulator stores potential energy in the form of pressurized fluid. It releases this energy during periods of high demand or system failure.

🥪 Types:

- Weight-loaded accumulator

- Spring-loaded accumulator

- Gas-loaded accumulator (bladder or piston type)

🛠️ Uses:

- Provide sudden bursts of energy

- Stabilize hydraulic systems

- Emergency hydraulic pressure source

🔍 Importance in Civil Engineering Projects

Hydraulic machines are essential in:

- 🚜 Construction Equipment: Jacks, presses, hydraulic arms

- 🚿 Water Distribution Systems: Pumps for supply & drainage

- ⚡ Hydropower Projects: Turbines for electricity generation

- 🌾 Irrigation Networks: Centrifugal pumps and regulators

- 🌉 Bridge Lifting & Maintenance: Hydraulic lifts and presses

📊 Governing Equations and Efficiencies

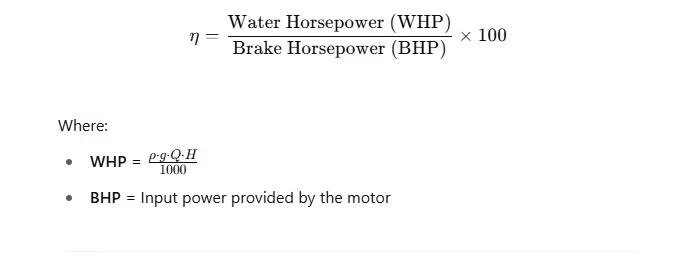

✅ Efficiency of a Turbine:

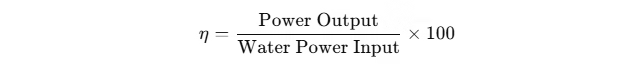

✅ Efficiency of a Pump:

📚 Real-world Applications

| Machine | Project Example | Region |

|---|---|---|

| Pelton Turbine | Uri Hydropower Project | J&K |

| Kaplan Turbine | Teesta Low-Head Plant | Sikkim |

| Centrifugal Pump | Srinagar Water Supply Scheme | J&K Municipal Systems |

| Hydraulic Jack | Chenab Bridge Construction | J&K |

🧠 Memory Tricks for Exams

- Pelton = Pressure (High Head)

- Kaplan = Kalm Water (Low Head)

- Centrifugal = City Water Supply

- Reciprocating = Rail-pump (high pressure)

🔚 Detailed Conclusion

Hydraulic machines form a cornerstone in fluid mechanics and infrastructure development in civil engineering. From lifting tons of structural components to powering irrigation networks and hydro plants, these devices rely on fundamental principles like Pascal’s Law, Bernoulli’s Equation, and Energy Conservation.

For JKSSB Civil Engineering exams, mastering these machines not only helps in scoring well in fluid mechanics but also in construction practices, irrigation engineering, and environmental systems.

Pro Tip: Always pair theoretical understanding with formula revision and solve previous year questions.

📌 Join our Telegram Channel JKSSB CivilsCentral for regular updates, quizzes, PDF notes, and practice sets curated specifically for JKSSB aspirants.