🏠 What is Non-Destructive Testing in Concrete?

Non-Destructive Testing (NDT) refers to a collection of evaluation methods used to assess the physical and structural condition of concrete without causing any damage to the structure. These methods are especially valuable when inspecting concrete in situations where taking samples or conducting destructive tests is impractical or unsafe.

NDT helps determine properties such as compressive strength, homogeneity, presence of internal flaws like voids or cracks, and the location of reinforcement, all without harming the structure. It is widely used for quality control during construction, diagnosis of deteriorating structures, and long-term health monitoring of vital civil infrastructure like dams, flyovers, and high-rise buildings.

Unlike Destructive Testing, which involves extracting concrete samples for crushing or lab testing, NDT enables in-situ testing, offering results in real-time and facilitating prompt decision-making for maintenance and repair.

📚 Applications of NDT in Civil Engineering

| Application | Explanation |

|---|---|

| Structural Health Monitoring | Detect cracks, honeycombing, voids, or delaminations. |

| Quality Control on Site | Check compressive strength and integrity without core cutting. |

| Evaluation of Old Structures | Assess strength and remaining life of aged concrete. |

| Repair and Retrofitting Decisions | Helps in selecting zones that require strengthening. |

| Bridge and Pavement Monitoring | Used in roads, flyovers, and rail tracks for periodic evaluation. |

🧪 Detailed Explanation of Major NDT Methods

1️⃣ Rebound Hammer Test (Schmidt Hammer)

- Principle: Based on the surface hardness of concrete — a spring-driven mass strikes the surface, and the rebound distance is recorded.

- Formula Used: Empirical correlation between Rebound Number and compressive strength.

- Usage:

- Quick estimate of compressive strength.

- Mapping strength across different regions of the same structure.

- Limitations:

- Only surface hardness, not internal condition.

- Not reliable for concrete with coarse aggregates or surface carbonation.

🔎 IS Code: IS 13311 (Part 2)

2️⃣ Ultrasonic Pulse Velocity (UPV) Test

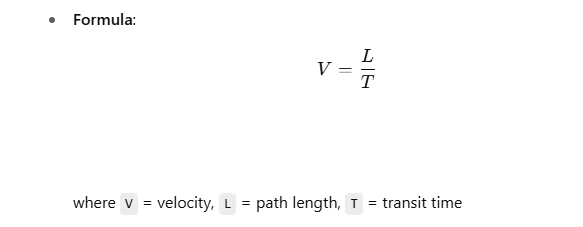

- Principle: Measures the velocity of ultrasonic waves passing through concrete. Velocity depends on density and elasticity of the material.

- Setup: Transmitter and receiver placed on either side (direct, semi-direct, or indirect transmission).

- Interpretation:

| Velocity (km/s) | Quality of Concrete |

|---|---|

| > 4.5 | Excellent |

| 3.5 – 4.5 | Good |

| 3.0 – 3.5 | Medium |

| < 3.0 | Poor |

- Advantages:

- Detects internal flaws.

- Indicates uniformity.

- Used in structural audits.

🔎 IS Code: IS 13311 (Part 1)

3️⃣ Penetration Resistance Test (Windsor Probe)

- Principle: Steel probes are shot into concrete using a controlled force. Penetration depth is inversely related to compressive strength.

- Advantages:

- Reliable in-field strength estimation.

- Can be used on large structures like bridge decks or columns.

- Limitations:

- Results vary with aggregate size and type.

- Creates small holes (semi-destructive).

4️⃣ Pull-Out Test

- Principle: A specially cast insert is pulled out from concrete using hydraulic force. The pull-out force correlates with concrete strength.

- Application:

- Measures in-situ compressive strength.

- Useful for early strength monitoring.

- Advantage: More reliable than surface-based tests like rebound hammer.

- Limitation: Semi-destructive; leaves a small cavity.

5️⃣ Impact Echo Test

- Principle: Generates stress waves on the concrete surface; reflected waves indicate flaws like voids or delaminations.

- Applications:

- Locating internal cracks, honeycombing, debonding of overlays.

- Commonly used in bridge decks, slabs, tunnels.

- Benefit: Accurate flaw depth estimation.

6️⃣ Ground Penetrating Radar (GPR)

- Principle: Emits electromagnetic pulses and detects reflections from embedded objects or changes in material.

- Applications:

- Locating reinforcement bars, cables.

- Assessing thickness of pavement layers.

- Detecting moisture ingress or delaminations.

- Limitation: Accuracy depends on moisture content and material properties.

7️⃣ Radiographic Testing (X-ray/Gamma Ray)

- Principle: High-energy rays pass through concrete. Defects appear as shadows or dark spots on a film or sensor.

- Used For:

- Detection of internal defects in critical structures.

- Quality check in precast units or nuclear structures.

- Limitation: Expensive, requires safety precautions.

📊 Comparative Table: Major NDT Methods

| Test | Type | Accuracy | Used For | Damage |

|---|---|---|---|---|

| Rebound Hammer | Surface | Low–Moderate | Strength estimate | None |

| UPV | Internal | High | Homogeneity, cracks | None |

| Windsor Probe | Semi-surface | Moderate | Strength | Minor |

| Pull-Out | Semi-destructive | High | In-situ strength | Small cavity |

| Impact Echo | Internal | High | Flaws, voids | None |

| GPR | Subsurface | High | Rebar detection | None |

| Radiography | Internal | Very High | Density, defects | None |

📝 Best Practices While Performing NDT

- Calibrate instruments as per IS codes.

- Use multiple NDT methods for accuracy (e.g., UPV + Rebound Hammer).

- Maintain consistent surface conditions during testing.

- Conduct statistical analysis on multiple readings.

- Ensure proper training and certification of test operators.

🧠 Tips for JKSSB Civil Engineering Exam

- Memorize the IS Codes:

- IS 13311 (Part 1) – UPV

- IS 13311 (Part 2) – Rebound Hammer

- Prepare MCQs based on principles and usage:

- E.g., “Which test is used to locate honeycombing?”

- Focus on:

- Application-based reasoning

- Comparative advantages/disadvantages

- Interpretation of results (velocity ranges, rebound numbers)

🏁 Conclusion: Importance of NDT in Modern Concrete Engineering

Non-Destructive Testing (NDT) plays a critical role in modern concrete technology by offering an effective, economical, and reliable way to assess the integrity, strength, and durability of concrete structures without compromising their serviceability. In the context of increasing infrastructure demands and aging structures, NDT has become a vital tool for civil engineers to ensure safety, monitor deterioration, and make informed decisions regarding repair, rehabilitation, or strengthening.

Techniques like the Rebound Hammer Test and Ultrasonic Pulse Velocity (UPV) Test are widely accepted for quality control during construction, while advanced methods such as Ground Penetrating Radar (GPR) and Impact Echo help detect hidden defects in old structures. These methods not only save time and cost but also minimize risk by eliminating the need for destructive sampling.

For JKSSB Civil, SSC JE, and similar competitive exams, understanding the principles, advantages, limitations, and practical applications of each NDT method is essential. Questions are often framed around test names, IS codes, measured parameters, and interpretation of results.

To sum up, mastering NDT techniques not only strengthens your exam preparation but also equips you with essential skills for real-world engineering practices — ensuring both structural longevity and public safety.

📌 Frequently Asked Questions (FAQs)

❓1. What is the purpose of Non-Destructive Testing in concrete?

Answer: The main purpose is to assess the strength, durability, and internal condition of concrete structures without damaging them. It is useful for quality control, structural health monitoring, and repair decisions.

❓2. Which IS codes are related to NDT methods in concrete?

Answer:

- IS 13311 (Part 1): Ultrasonic Pulse Velocity Test

- IS 13311 (Part 2): Rebound Hammer Test

❓3. Which NDT test is used to detect internal flaws in concrete?

Answer: Ultrasonic Pulse Velocity (UPV) and Impact Echo tests are used to detect internal flaws like cracks, honeycombing, and delaminations.

❓4. Is the Rebound Hammer test reliable for all types of concrete?

Answer: No, it is less reliable for concrete with coarse aggregates, wet surfaces, or carbonated layers. It only gives an estimate based on surface hardness.

❓5. What does a UPV value of less than 3.0 km/s indicate?

Answer: It indicates poor quality concrete with possible voids, cracks, or low density.

❓6. Are all NDT methods completely non-destructive?

Answer: No, some like Pull-Out Test and Windsor Probe are considered semi-destructive because they cause minor damage like small holes.

❓7. Why is it recommended to use more than one NDT method?

Answer: Because using multiple methods increases accuracy and gives a more comprehensive understanding of the concrete condition.

📘 PYQs (Previous Year Questions)

These are based on JKSSB JE, SSC JE, and similar civil engineering exams:

✅ Q1. Which of the following is a Non-Destructive Test for concrete?

A) Cube Compression Test

B) Rebound Hammer Test

C) Split Tensile Strength Test

D) Flexural Strength Test

✔️Correct Answer: B) Rebound Hammer Test

✅ Q2. IS 13311 (Part 1) refers to which test?

A) Rebound Hammer Test

B) Pull-Out Test

C) Ultrasonic Pulse Velocity Test

D) Radiographic Test

✔️Correct Answer: C) Ultrasonic Pulse Velocity Test

✅ Q3. In a Rebound Hammer Test, the rebound number is related to:

A) Density of concrete

B) Surface hardness

C) Tensile strength

D) Modulus of elasticity

✔️Correct Answer: B) Surface hardness

✅ Q4. In which test is the velocity of ultrasonic waves measured?

A) Pull-Out Test

B) Impact Echo Test

C) Ultrasonic Pulse Velocity Test

D) Rebound Hammer Test

✔️Correct Answer: C) Ultrasonic Pulse Velocity Test

✅ Q5. Which of the following is a semi-destructive NDT method?

A) Impact Echo

B) UPV Test

C) Pull-Out Test

D) Radiography

✔️Correct Answer: C) Pull-Out Test

✅ Q6. In UPV testing, high velocity indicates:

A) Poor concrete

B) Excellent concrete quality

C) Presence of cracks

D) High moisture content

✔️Correct Answer: B) Excellent concrete quality

📌 Join our Telegram Channel JKSSB CivilsCentral for regular updates, quizzes, PDF notes, and practice sets curated specifically for JKSSB aspirants.