🔰 Introduction to RCC (Reinforced Cement Concrete)

Reinforced Cement Concrete (RCC) is a composite material made by combining concrete (cement + sand + aggregates + water) and reinforcement steel bars (rebars). Concrete handles compression, and steel bars handle tension—this synergy makes RCC highly durable and widely used in structural components like beams, columns, slabs, and footings.

This combination leverages the best properties of both materials:

- Concrete is strong in compression but weak in tension.

- Steel is ductile and strong in tension but expensive for use alone.

By embedding steel bars in zones of tensile stress within concrete, the structure becomes capable of withstanding multiple loading conditions such as bending, shear, axial force, and torsion. RCC provides the advantage of monolithic behavior, allowing members to act together rather than individually.

RCC structures are widely used in:

- Buildings: framed structures, high-rise buildings

- Bridges: decks, piers

- Foundations: footings, pile caps

- Infrastructure: dams, retaining walls, tunnels

RCC also enables flexibility in architectural design, low maintenance, and long-term durability when constructed with quality materials and proper detailing.

📌 Key Features of RCC:

- Excellent compressive strength

- Good durability and fire resistance

- Easily moulded into any shape

- Works well in tension and compression zones when reinforced

🎯 Why This Topic Matters for JKSSB Aspirants?

Questions related to design philosophies, IS 456:2000, and Limit State Design are common in exams like JKSSB JE Civil, SSC JE, and AE/State-level civil exams. Understanding the theoretical base of RCC design methods helps in solving MCQs accurately.

📊 What is Structural Design?

Structural design is the process of planning, analyzing, and designing structures so they can safely resist all applied loads without failure during their intended life.

It involves:

- Determining the internal forces (bending moment, shear force)

- Calculating required cross-sectional areas and reinforcement

- Ensuring both strength and serviceability

🔀 Design Philosophies in RCC

1️⃣ Working Stress Method (WSM)

🔍 What is Working Stress Method?

The Working Stress Method (WSM) is one of the earliest and traditional methods of RCC design. It is based on linear elastic theory that assumes the structure behaves elastically under service loads and the stress is directly proportional to strain (Hooke’s Law). The structure is designed to remain within the elastic limit of both concrete and steel.

📐 Key Assumptions of WSM

- Stress-Strain Relationship for both concrete and steel is linear.

- Perfect bond exists between concrete and reinforcement.

- Plane sections remain plane after bending (i.e., strain distribution is linear).

- The structure will not exceed permissible stress levels under service loads.

- The factor of safety (FoS) is applied only to materials, not loads.

🧱 Working Principle

- The structure is designed for service load conditions (i.e., the actual load expected during its use).

- Material strengths are divided by a factor of safety to obtain permissible stresses.

- The internal stresses developed in the materials due to service loads must not exceed these permissible stresses.

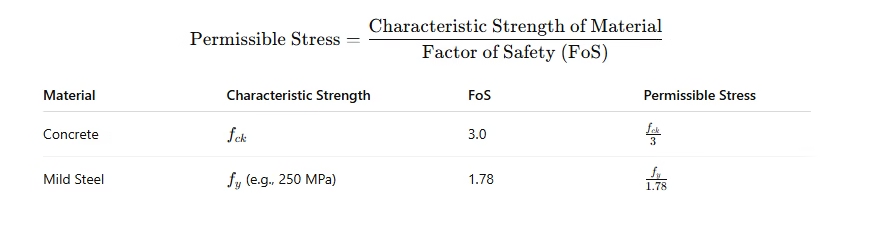

🔣 Important Formulae in WSM

🔹 Permissible Stress:

📊 Example of Permissible Stress Calculation:

Let’s say,

🔍 Design Steps in WSM

- Assume cross-section and estimate loads.

- Calculate bending moment, shear force, axial load, etc.

- Compute stresses in steel and concrete under service load.

- Check that these stresses are less than the permissible values.

- Modify section if permissible stresses are exceeded.

⚖️ Factor of Safety (FoS) in WSM

| Material | Factor of Safety |

|---|---|

| Concrete | 3.0 |

| Steel | 1.78 (mild steel), 1.5 (HYSD) |

📉 Limitations of WSM

- Ignores actual behavior of materials near collapse.

- Assumes no redistribution of moments (unrealistic for indeterminate structures).

- Overly conservative → uneconomical.

- Cannot ensure serviceability criteria such as deflection and cracking.

- Not suitable for modern high-rise and complex structures.

🧾 Where is WSM Still Used?

Despite being mostly obsolete, WSM is still used in:

- Design of water-retaining structures (e.g., tanks, reservoirs)

- Pre-stressed concrete design

- Masonry and some hydraulic structures

- Educational purposes to understand fundamentals

📚 Reference from IS Code

- IS 456:2000 (Clause 18) recommends Limit State Method, but also permits WSM for special cases.

- Earlier versions of IS 456 were entirely based on WSM before LSM was introduced.

💡 Conceptual Summary

| Aspect | Working Stress Method (WSM) |

|---|---|

| Basis | Elastic Theory |

| Stress Assumption | Linear (Hooke’s Law) |

| Material Safety | Factor of safety applied on materials |

| Serviceability | Assumed automatically ensured |

| Collapse Load | Not considered |

| Economy | Over-conservative → Less economical |

| Current Use | Obsolete for general use; special cases only |

2️⃣ Ultimate Load Method (ULM)

🔍 What is Ultimate Load Method?

The Ultimate Load Method (ULM) is a design philosophy where structures are designed based on their maximum load-carrying capacity—also known as the ultimate load or collapse load. Unlike the Working Stress Method, ULM does not focus on permissible stress levels under service conditions but rather ensures the structure will not collapse under extreme loading conditions.

🧠 Fundamental Concept

- In ULM, loads are factored up (increased) using Load Factors, and the strength of the material is considered in full (without reduction by safety factors).

- The main concern is to make sure the structure doesn’t fail catastrophically under the worst possible loading condition.

🧱 Assumptions of ULM

- Structure behaves elastically up to yield, then enters plastic (nonlinear) behavior before failure.

- Partial safety factor is applied to loads only, not to materials.

- Plastic redistribution of moments is allowed in indeterminate structures.

- Collapse is sudden, so safety against failure is the only concern.

- Serviceability (deflection, cracking) is not checked.

🔢 Basic Formula

Example:

If working load = 50 kN

and load factor = 1.5,

then ultimate load = 50 × 1.5 = 75 kN

📏 Load Factors Used in ULM

| Type of Load | Load Factor (Typical) |

|---|---|

| Dead Load (DL) | 1.5 |

| Live Load (LL) | 1.5 |

| Wind Load (WL) | 1.5 or 1.2 |

| Earthquake Load | 1.2 or 1.5 |

(Note: These were later refined in LSM.)

🛠️ Design Process in ULM

- Estimate dead, live, and other loads on structure.

- Multiply each load by its corresponding load factor.

- Compute factored moments and forces (ultimate conditions).

- Design the structure such that it resists these factored loads without collapse.

✅ Advantages of ULM

- Simpler and more realistic than WSM when considering actual material strength.

- Allows moment redistribution—beneficial in indeterminate structures.

- More economical than WSM due to reduced conservatism.

- Gave early insight into load behavior at collapse and nonlinear strength.

❌ Limitations of ULM

- Does not account for serviceability (e.g., cracking, deflection).

- Neglects long-term durability, which is important for structure lifespan.

- Unsafe under sustained loads, as material deformation is not controlled.

- No clear method to evaluate comfort, aesthetics, and vibrations.

- Abandoned in favor of Limit State Method (LSM) in modern design.

🏗️ Historical Context

- Gained popularity during the mid-20th century (1950s–70s).

- Seen as an improvement over WSM due to its realistic collapse-based approach.

- Provided groundwork for the Limit State Method, which balanced both strength and serviceability.

📘 Code Reference

- Early revisions of RCC design codes (before IS 456:1978) included ULM.

- IS 456:2000 no longer recommends ULM—it endorses Limit State Method as the standard.

- ULM is now only of academic interest or used in understanding plastic design.

🧾 ULM vs. Other Methods

| Feature | Working Stress Method | Ultimate Load Method | Limit State Method (Current) |

|---|---|---|---|

| Based On | Elastic Theory | Ultimate Strength | Probabilistic + Limit States |

| Safety Factor On | Material Strength | Loads | Both Loads & Material |

| Serviceability | Assumed | Not considered | Explicitly considered |

| Economy | Low (conservative) | Moderate | High |

| Realism | Low | Moderate | High |

| Current Status | Obsolete | Obsolete | Widely Adopted |

🧠 Summary

- Ultimate Load Method was a transition method between conservative WSM and modern LSM.

- It served as an intermediate step in understanding material capacity under failure loads.

- However, it lacked attention to comfort and long-term usability—making it unsuitable for modern-day structures.

3️⃣ Limit State Method (LSM) ✅ Most Modern & Adopted

🔍 What is Limit State Method?

The Limit State Method (LSM) is the most widely used and recommended design method for Reinforced Cement Concrete (RCC) structures today. It ensures that structures are:

- Safe against collapse (strength limit states),

- Functional during service life (serviceability limit states),

- And economical in material use.

It is a hybrid method that combines the best aspects of Working Stress Method (WSM) and Ultimate Load Method (ULM) while overcoming their limitations.

🧠 Core Concept of LSM

- Design is done for both limit states:

- Limit State of Collapse (Strength)

- Limit State of Serviceability (Deflection, Cracking, Vibration, etc.)

- Uses partial safety factors on both loads and material strengths.

- Based on probabilistic and statistical principles — considers variability in loads and material properties.

🧱 Types of Limit States in LSM

| 🔴 Limit State | ✅ What it Ensures | 🏗️ Examples |

|---|---|---|

| Collapse (Strength) | No failure due to ultimate loads | Flexure, shear, torsion, axial load |

| Serviceability | Comfort and usability during service life | Deflection, cracking, vibrations |

| Durability | Long-term structural performance | Exposure conditions, cover depth |

| Fire Safety | Resistance to high temperature | Fire ratings and stability |

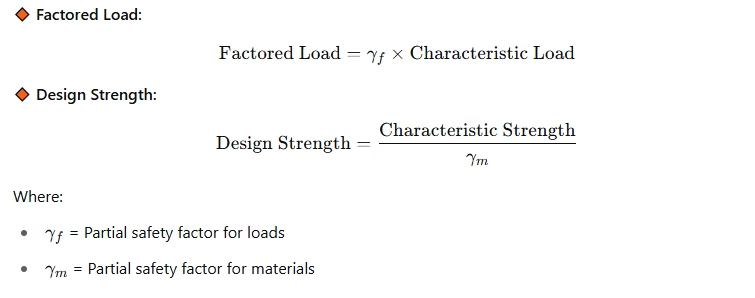

📋 Basic Design Formula

📊 Typical Safety Factors in LSM (IS 456:2000)

| Quantity | Load Factor (γₙ) | Material Factor (γₘ) |

|---|---|---|

| Dead Load | 1.5 | |

| Live Load | 1.5 | |

| Wind / Earthquake Load | 1.2 | |

| Concrete (Limit state of collapse) | 1.5 | |

| Steel (Limit state of collapse) | 1.15 |

🧾 Design Procedure in LSM

- Estimate loads: Dead load, live load, wind load, etc.

- Apply partial safety factors to compute factored load.

- Determine design strength using reduced (factored) material strengths.

- Design sections for bending, shear, torsion, etc.

- Check serviceability for deflection, crack width, etc.

- Ensure durability via appropriate cover, material grade, exposure checks.

✅ Advantages of LSM

- Comprehensive: Considers both strength and serviceability.

- Realistic: Based on actual failure probability and load variability.

- Safe & Economical: Balances material savings with structural safety.

- Flexible: Supports redistribution of moments in indeterminate structures.

- Mandatory in IS 456:2000 – making it exam-relevant and industry-standard.

❌ Limitations of LSM

- Requires more complex calculations and judgment.

- Probabilistic approach needs assumptions about variability.

- Overdesign may occur if partial safety factors are conservatively chosen.

- Designers must be cautious in crack control and durability checks.

🧘♂️ Philosophical Comparison

| Feature | WSM | ULM | LSM ✅ (Modern) |

|---|---|---|---|

| Safety Factor On | Material | Load | Both Load and Material |

| Approach | Elastic | Collapse (Plastic) | Probabilistic & Practical |

| Stress-Strain | Linear | Non-linear | Non-linear |

| Serviceability | Assumed | Ignored | Explicitly Checked |

| Moment Redistribution | ❌ Not Allowed | ✅ Allowed | ✅ Allowed |

| Economy | ❌ Less | ✅ Moderate | ✅ Most Economical |

| Status in IS Codes | Obsolete | Obsolete | ✅ Recommended |

📘 Code Reference

- IS 456:2000 — Limit State Method is mandatory for RCC design.

- Limit states are discussed in detail from Clause 36 onwards.

- Partial safety factors are given in Table 18 and 19 of the IS code.

💡 Real-Life Applications of LSM

- Buildings and residential flats

- High-rise towers

- Bridges, flyovers, tunnels

- Hydraulic structures

- Marine and offshore RCC works

📚 Example for Better Understanding

Let’s say:

- Characteristic Dead Load = 20 kN

- Characteristic Live Load = 15 kN

- Characteristic Strength of concrete = M25 → 25 MPa

- Partial Safety Factors: DL = 1.5, LL = 1.5, Concrete = 1.5

Then:

- Factored Load = (20 × 1.5) + (15 × 1.5) = 52.5 kN

- Design Strength of Concrete = 25 / 1.5 = 16.67 MPa

You now check that under 52.5 kN, the compressive stress developed in concrete does not exceed 16.67 MPa.

🧠 Summary of Limit State Method (LSM)

| Aspect | Details |

|---|---|

| Design Basis | Safety + Serviceability |

| Factors Used | Partial Safety Factors (Loads, Materials) |

| Material Behavior | Non-linear, Realistic |

| Service Life Considered | ✅ Yes |

| Code Compliance | ✅ IS 456:2000 |

| Use in Exams | ✅ Very important for JKSSB/SSC |

📊 Comparison Table of RCC Design Philosophies

| Feature | WSM | ULM | LSM (Adopted) |

|---|---|---|---|

| Based On | Elastic theory | Ultimate load theory | Probabilistic approach |

| Safety Factor | On material | On loads | On both |

| Serviceability | Considered | Not considered | Considered |

| Economy | Less economical | Moderately economical | Most economical |

| Status | Obsolete | Obsolete | ✅ Widely used (IS 456) |

📚 IS Code Reference

- IS 456:2000 – Code of practice for RCC design

- SP-16 – RCC Design Aids

- SP-34 – Reinforcement Detailing

- IS 875 – Structural Loads

📍 PYQ from JKSSB and SSC

Q: Which design philosophy is currently used in RCC as per IS 456:2000?

A. Working Stress Method

B. Ultimate Load Method

C. Limit State Method ✔️

D. None of the above

🙇 FAQs on RCC Design Philosophies

Q1. Why is the Limit State Method preferred today?

Ans: Because it considers both safety and serviceability, making structures safe, functional, and economical.

Q2. Is Working Stress Method still used?

Ans: Rarely. It’s still used in specific structures like liquid retaining structures and pre-stressed members.

Q3. What is the partial safety factor for concrete in LSM?

Ans: 1.5 (as per IS 456:2000)

🧠 Conclusion

Understanding the evolution of RCC design methods helps grasp modern construction practices. While WSM and ULM played historical roles, the Limit State Method is the standard today—balancing safety, economy, and durability. Mastering these fundamentals is crucial for JKSSB Civil, SSC JE, and other exams.

📌 Join our Telegram Channel JKSSB CivilsCentral for regular updates, quizzes, PDF notes, and practice sets curated specifically for JKSSB aspirants.