📌 Introduction

In RCC (Reinforced Cement Concrete) structures, shear and torsion are two critical internal actions that must be rigorously addressed during structural design. While flexural (bending) stresses often dominate, shear forces—which attempt to induce relative sliding between adjacent sections of concrete—and torsional forces—which twist a member about its longitudinal axis—can lead to brittle and sudden failures if not properly accounted for. Unlike flexural failure, which offers visible warnings like deflection and cracking, shear and torsion failures are often abrupt. Hence, understanding their behavior and providing adequate reinforcement as per IS 456:2000 is vital for the safety and serviceability of RCC members, especially in beams with concentrated loads or geometric irregularities such as curved or L-shaped configurations.

🔎 Why this topic matters for JKSSB?

- Regularly asked in JKSSB JE/AE Civil technical papers

- Strong conceptual base helps in tackling design-based numericals

- Also relevant for structural engineering interviews

🧪 Shear in RCC Beams

▪️ What is Shear?

Shear force tries to slide one part of a beam section relative to another, creating diagonal tensile stresses in the concrete. Since concrete is inherently weak in tension, especially diagonal tension, it is particularly vulnerable to shear-induced cracking. These cracks typically initiate at the neutral axis and propagate diagonally toward the supports. If unaddressed, they may lead to brittle shear failure. To counteract this, steel reinforcement in the form of stirrups or bent-up bars is strategically placed within the beam to intercept these cracks and provide ductility and strength to the section.

▪️ Types of Shear

- Vertical Shear (Main Type)

This is the direct shear acting perpendicular to the axis of the beam, primarily caused by transverse loading. It results in vertical shear forces that must be resisted to prevent sudden failure near supports. Concrete is capable of resisting limited vertical shear, but beyond a threshold, steel stirrups are essential. - Diagonal Shear (Causes inclined cracks near supports)

Diagonal shear occurs due to the combination of vertical shear and flexural stresses, producing inclined tension cracks near the supports. These cracks usually initiate from the tension side of the beam and angle toward the compression zone. This is the most dangerous type of shear cracking, often leading to brittle failure if not intercepted with sufficient reinforcement such as vertical stirrups or bent-up bars.

▪️ Shear Reinforcement in RCC

Shear reinforcement is provided using:

- Vertical stirrups: These are closed-loop steel bars placed vertically around the longitudinal reinforcement of the beam. They resist vertical shear and help in preventing diagonal tension cracks. They are the most common type of shear reinforcement and are easy to place and tie during construction.

- Bent-up bars: These are a part of the main longitudinal reinforcement, bent upward at specific locations (usually near supports) to intercept shear cracks. They act in combination with stirrups to resist diagonal shear but are less commonly used now due to challenges in placement and inspection.

- Inclined stirrups: These are stirrups inclined at an angle (usually 45°) to the horizontal axis of the beam. They are effective in resisting diagonal tension directly but are not often preferred in practice due to complexity in placement. However, they can provide better crack control compared to vertical stirrups.

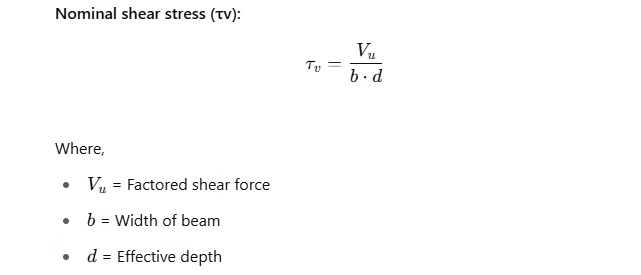

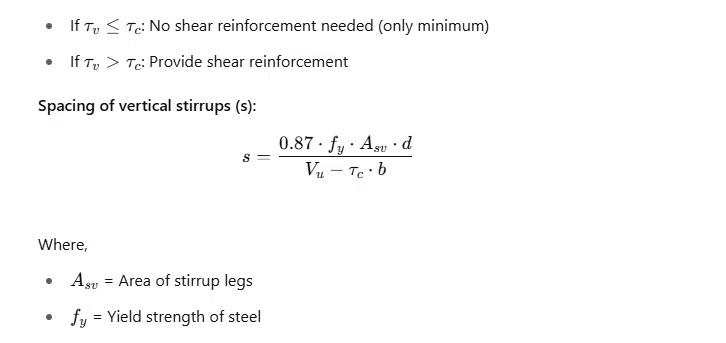

▪️ Design of Shear Reinforcement (IS 456:2000 Guidelines)

Compare τv with permissible shear stress (τc):

🌀 Torsion in RCC Beams (IS 456:2000 Guidelines)

Torsion plays a critical role in the design of beams, especially when structural elements are subjected to twisting moments due to irregular geometry or loading conditions. Unlike bending and shear which act in the plane of the beam, torsion is an out-of-plane force that causes the beam to twist along its longitudinal axis.

🔹 What is Torsion?

Torsion is the twisting of a structural element (like a beam or slab) due to the action of torque or a moment acting about its longitudinal axis. Torsion usually arises in:

- L-shaped, T-shaped, or curved beams

- Spandrel beams in framed structures

- Edge beams of slabs and cantilevers

When torsional effects are not accounted for properly, they may lead to diagonal tension cracks, excessive deformation, or even collapse.

🔹 Types of Torsion in RCC

- Primary Torsion

- Torsion that must be structurally resisted.

- Common in cases where torsional moment is a part of the main load path.

- Requires full reinforcement design.

- Secondary Torsion

- Also called compatibility torsion.

- Arises due to restraint or monolithic behavior.

- Often self-balanced within the structural system.

- May not require full torsional reinforcement.

🔸 IS 456:2000 recommends that secondary torsion may be ignored or given limited reinforcement.

🔹 Design of RCC Beams for Torsion (IS 456:2000)

When torsion acts along with bending and shear, the beam is designed for equivalent forces:

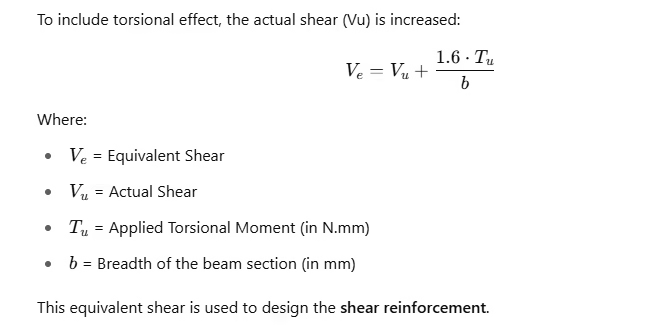

✅ 1. Equivalent Shear Force (Ve)

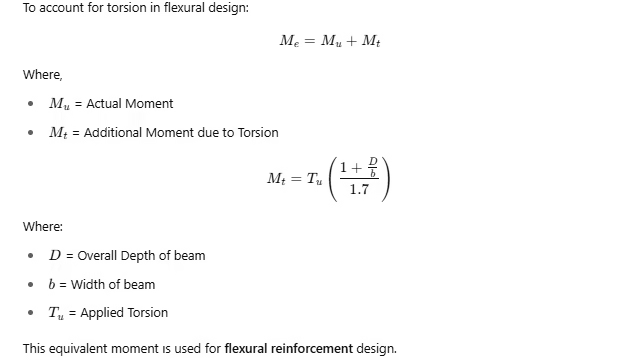

✅ 2. Equivalent Bending Moment (Me)

🔹 Torsional Reinforcement

- Torsional moments induce shear stresses on all four faces of a rectangular section.

- Reinforcement consists of:

- Closed rectangular stirrups (ties) around the tension zone

- Longitudinal bars in corners to resist torsional stresses

- Reinforcement must form a closed cage to act effectively.

✅ IS 456:2000 suggests using the greater of flexural or torsional reinforcement wherever torsion is significant.

🔹 When to Consider Torsion in RCC Design

Torsion must be designed for when:

- Beams are connected to slabs at different levels

- Cantilever arms or brackets are present

- Curved beams or spandrels are part of the structure

- Openings or irregular loadings cause eccentricities

🧠 Memory Tricks

- “STIR” = Shear → TIRrups

- “Torsion = Twist” → Requires both longitudinal + transverse reinforcement

- For torsion, add 1.6×T/b to shear (easy to remember for Ve formula)

📊 Shear vs Torsion – Quick Comparison Table

| Aspect | Shear | Torsion |

|---|---|---|

| Nature | Sliding force | Twisting force |

| Main reinforcement | Stirrups | Stirrups + Longitudinal bars |

| Failure mode | Diagonal tension | Spiral cracking/twisting |

| Design approach | Based on τv and τc | Based on equivalent moment/shear |

📘 PYQs (JKSSB/SSC Pattern)

- In RCC, the main reinforcement to resist shear is:

a) Longitudinal bars

b) Bent-up bars

c) Stirrups ✔️

d) None - Torsional reinforcement is designed based on:

a) Pure bending

b) Equivalent moment and shear ✔️

c) Only shear

d) None of these - If τv < τc, what type of shear reinforcement is provided?

a) Maximum

b) Nominal ✔️

c) Zero

d) None

🙋♂️ FAQs

Q1. Is torsion commonly encountered in simply supported beams?

Ans: No, torsion mainly appears in irregular or curved beams like in balconies or spiral stairs.

Q2. Are bent-up bars sufficient for torsion?

Ans: No, torsion requires both longitudinal and transverse reinforcement.

Q3. Why is concrete weak in shear and torsion?

Ans: Because both are tensile-dominated behaviors and concrete is weak in tension.

✅ Conclusion

The design of shear and torsion in RCC plays a critical role in ensuring structural safety and durability. For JKSSB and other exams, understanding the formulas, IS 456 guidelines, and failure mechanisms is essential. Always remember that torsion is more demanding than shear and requires combined reinforcement strategies.

📌 Join our Telegram Channel JKSSB CivilsCentral for regular updates, quizzes, PDF notes, and practice sets curated specifically for JKSSB aspirants.