📅 Updated on: August 1, 2025

🔍 What is Prestressed Concrete?

Prestressed concrete is a form of concrete where internal compressive stresses are intentionally introduced before applying service loads. This counters the tensile stresses that develop under working loads, minimizing cracking and improving structural performance.

🧠 Concept Behind Prestressing:

Concrete is strong in compression but weak in tension. By prestressing, we “preload” the member with compressive forces so that when tensile stresses due to applied loads act, they are neutralized or reduced.

🛠️ Types of Prestressing Methods in RCC

| Type | Description |

|---|---|

| Pre-tensioning | Tendons are tensioned before concrete is cast. Common in precast factories. |

| Post-tensioning | Tendons are tensioned after concrete has hardened. Used on construction sites. |

🔸 JKSSB Tip: Expect MCQs on difference between pre- and post-tensioning in exams.

🧱 Materials Used in Prestressed Concrete

1. Concrete

- Should have high early strength and low creep & shrinkage.

- Minimum grade:

- Pre-tensioned: M40

- Post-tensioned: M30–M40 (as per IS:1343)

2. Steel Tendons

- These are essential components in prestressed concrete, as they bear the tensioning force and transfer it effectively to the concrete.

- Common types:

- 7-wire strands: Widely used in post-tensioned members; composed of six wires helically wound around a central wire. High ductility and anchorage efficiency.

- Plain high-tensile wires: Typically used in pre-tensioned members; single straight wires with uniform stress distribution.

- Bars: High-strength deformed or plain bars are used where larger cross-sectional areas are needed.

- The yield strength of these materials usually ranges between 1570 MPa and 1860 MPa.

- The steel must have low relaxation properties and high fatigue strength to withstand long-term loading without significant loss of prestress.

3. Anchorages

- Transfer prestress from steel to concrete

- Anchorages serve as the key interface to safely transfer high tensile forces from steel tendons to the surrounding concrete.

- These must be designed to ensure a uniform distribution of stress, prevent slippage, and resist sudden failure.

- Common anchorage systems include wedges, bearing plates, and grout-filled sleeves depending on the prestressing method used.

- In post-tensioning, proper grouting of ducts around the tendons also contributes to effective stress transfer and corrosion protection.

📊 Prestressed Concrete Design – Step-by-Step Procedure

✅ 1. Load Analysis

- Calculate factored Dead Load (DL), Live Load (LL), and Environmental Loads (Wind, Seismic, etc.)

- Use load combinations as per IS:456 and IS:1343

✅ 2. Assume Cross Section

- Choose standard shapes: I-section, T-section, or rectangular

- Estimate section dimensions based on span and loads

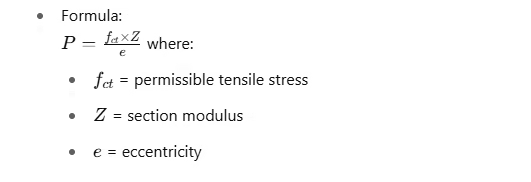

✅ 3. Calculate Required Prestressing Force (P)

✅ 4. Determine Eccentricity (e)

- Place tendons below neutral axis to introduce upward moment

- Maximize e within the section to reduce P

✅ 5. Stress Checks – At Transfer and Service Stages

Check:

- Compressive stress at top fiber

- Tensile stress at bottom fiber

- Should be within IS:1343 limits

✅ 6. Compute Losses in Prestress

| Type of Loss | Typical % Loss |

|---|---|

| Elastic shortening of concrete | 5–10% |

| Creep of concrete | 5–10% |

| Shrinkage of concrete | 3–5% |

| Relaxation of steel | 2–8% |

| Anchorage slip | 1–2% |

| Total loss | ~15–25% |

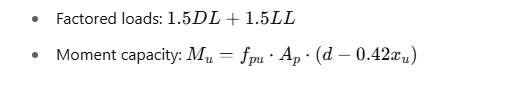

✅ 7. Ultimate Strength Check

Use Limit State of Collapse approach:

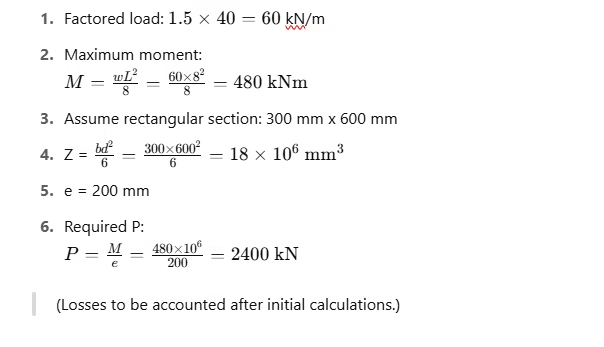

📏 Example Calculation (Simplified)

Given:

- Span: 8 m

- Load: 40 kN/m

- Concrete: M40

- Tendon: 7-wire strand (1860 MPa)

To Find:

- Prestressing force (P)

- Eccentricity (e)

Step-by-Step:

📊 Codal Provisions – IS:1343 (2012)

| Clause | Provision |

|---|---|

| 6.1 | Minimum grade of concrete |

| 8.2 | Permissible stresses in concrete & steel |

| 10 | Limit state design method |

| 18 | Losses in prestress (detailed formulas) |

| 22 | Durability requirements |

⚖️ Advantages of Prestressed RCC Over Conventional RCC

- Higher span-to-depth ratios

- Reduced section size → lighter structures

- Superior durability & crack control

- Economical for repetitive & long-span structures

⚠️ Design Errors to Avoid

- Underestimating prestress losses

- Wrong assumption of eccentricity

- Using low-strength concrete (< M40)

- Improper anchorage detailing

🌟 JKSSB/SSC JE-Oriented Study Tips

- Understand the prestressing concept vs conventional RCC

- Memorize key IS:1343 clauses & formulas

- Practice numerical questions on eccentricity & loss calculations

- Revise MCQs from past papers (JKSSB, SSC JE, RRB)

📝 Conclusion

The design of prestressed RCC members represents a cornerstone in the evolution of modern construction practices. These members are crucial for long-span bridges, high-rise buildings, silos, tanks, and structures subjected to heavy repetitive loads. For JKSSB Civil Engineering aspirants, it is not only important to understand the basic principles but also to appreciate the rationale behind codal provisions such as stress limits, cover requirements, tendon profiles, and loss calculations. Mastery of these concepts ensures structural safety, durability, and economic use of materials. Moreover, the ability to solve practical design problems and understand real-world applications enhances a candidate’s capability to score well in technical exams and contributes to competence in future professional roles.

❓ Frequently Asked Questions (FAQs)

1. What is prestressed concrete and why is it used?

Prestressed concrete is concrete in which internal stresses are introduced before external loading to counteract tensile stresses and control cracking. It enhances load capacity and service life of structures.

2. What is the difference between pre-tensioning and post-tensioning?

- Pre-tensioning: Tendons are tensioned before casting concrete (common in precast elements).

- Post-tensioning: Tendons are tensioned after concrete has hardened (used on-site).

3. What grade of concrete is used in prestressed members?

- Minimum M40 for pre-tensioned

- M30–M40 for post-tensioned concrete as per IS:1343

4. What are the common types of steel used in prestressing?

High-tensile steel such as:

- 7-wire strands

- High-tensile wires

- Bars with strength from 1570 MPa to 1860 MPa

5. What are the typical losses in prestress?

Losses range from 15–25% and include:

- Elastic shortening

- Creep & shrinkage of concrete

- Steel relaxation

- Anchorage slip

6. What is eccentricity in prestressed concrete design?

Eccentricity is the distance of the tendon from the neutral axis. It’s used to induce an upward bending moment to counteract external loads.

7. Is IS 456 used for prestressed design?

No. The main code is IS:1343–2012. However, IS 456 may still be referenced for basic load combinations and general requirements.

8. Can prestressed members have tension at the bottom fibers?

Yes, but within permissible tensile stress limits specified in IS:1343 to avoid cracking.

📘 PYQs (Previous Year Questions) – JKSSB, SSC JE, RRB JE

Q1. In prestressed concrete, which type of stress is intentionally induced before service load?

a) Tensile

b) Compressive ✔️

c) Shear

d) Torsional

Explanation: Compressive stress is induced to counteract future tensile stresses.

Q2. In post-tensioning method, tendons are tensioned:

a) Before casting concrete

b) After concrete hardens ✔️

c) During casting

d) None of the above

Q3. Which code deals specifically with prestressed concrete in India?

a) IS:456

b) IS:875

c) IS:1343 ✔️

d) IS:3370

Q4. What is the minimum grade of concrete for pre-tensioned members as per IS:1343?

a) M20

b) M30

c) M40 ✔️

d) M50

Q5. Which of the following is a typical loss in prestress?

a) Buckling

b) Elastic shortening ✔️

c) Shear failure

d) Slenderness

Q6. What is the main advantage of prestressed concrete over RCC?

a) More reinforcement

b) Higher dead load

c) Better crack control ✔️

d) Easier design

Q7. Tendons in prestressed concrete are made of:

a) Mild steel

b) Deformed bars

c) High-tensile steel ✔️

d) Cast iron

📌 Join our Telegram Channel JKSSB CivilsCentral for regular updates, quizzes, PDF notes, and practice sets curated specifically for JKSSB aspirants.