📅 Updated on August 1, 2025

🎯 Useful for: JKSSB JE Civil, SSC JE, RRB JE, State AE/JE Exams

📚 Subject: Reinforced Cement Concrete (RCC)

🔍 What is Bond in RCC?

Bond in RCC refers to the grip between reinforcing bars (rebars) and concrete that prevents slippage of steel under load. This bond ensures that the tensile forces carried by the steel are effectively transferred to the surrounding concrete. Without proper bond, concrete and steel cannot work together as a unified structural element, leading to a breakdown of the composite action—a fundamental concept in RCC design. Bond strength is influenced by several factors such as bar diameter, type of bar (plain or deformed), concrete grade, surface condition, and compaction during concreting. In practice, bond failure may manifest as cracks parallel to the reinforcement or sudden slippage, especially under high stress or poor construction quality. Ensuring good bond is crucial for maintaining structural integrity, especially in tension zones like beams and slabs.

🔗 Types of Bond in RCC

| Type of Bond | Description |

|---|---|

| Adhesion Bond | Chemical adhesion between concrete and steel. |

| Frictional Bond | Resistance due to surface roughness of bars. |

| Mechanical Bond | Achieved by using deformed bars (TMT), which mechanically interlock with concrete. |

📏 What is Development Length?

Development Length (Ld) is the minimum length of bar required to be embedded in concrete to develop its full strength in tension or compression without slipping. This length is necessary to ensure that the forces from the steel reinforcement are safely transferred to the surrounding concrete, enabling the structure to resist applied loads effectively. The concept of development length becomes critical at bar cut-off points, supports, or in areas where the reinforcement layout changes. Insufficient development length can cause bars to pull out of the concrete, leading to premature failure. It is especially important in cantilever beams, tension zones in slabs, and near column-beam joints. Development length also plays a key role in determining the lap length for splicing two reinforcement bars. The required development length is influenced by the type of steel, grade of concrete, bar diameter, and the level of stress in the bar.

📀 Development Length Formula (IS 456:2000)

📊 Design Bond Stress Values (as per IS 456:2000)

| Concrete Grade | Plain Bars (N/mm²) | Deformed Bars (N/mm²) |

|---|---|---|

| M20 | 1.2 | 1.6 |

| M25 | 1.4 | 1.9 |

| M30 | 1.5 | 2.0 |

✅ Multiply values by 1.25 for compression

✅ Multiply by 1.6 in case of confinement (e.g. stirrups or closely spaced bars)

📈 Factors Affecting Development Length

| Factor | Effect |

|---|---|

| Bar Diameter | Larger bars = more surface = more Ld |

| Concrete Grade | Higher grade = higher bond = shorter Ld |

| Bar Type | TMT/deformed bars = better grip = reduced Ld |

| Stress Level | Higher stress = longer Ld |

| Quality of Construction | Poor vibration = reduced bond = more Ld |

🧰 Practical Use: Where Development Length is Needed

- At supports of beams and slabs

- Where bars are terminated or bent

- In lap joints to connect rebars

- In columns at footing levels

- At points of bar curtailment or splice

📊 Example Problem

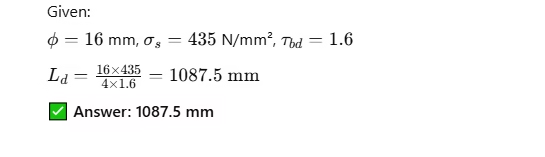

Q: Calculate development length of 16 mm Fe500 bar in M20 concrete.

✅ Answer: 1087.5 mm

📏 Hooks, Bends & Anchorage

- Standard Hook Length: 16×ϕ

- 90° Bend: 8×ϕ

- 135° Bend: 10×ϕ

- Anchorage Length is included when Ld cannot be fully provided.

❓ FAQs on Bond and Development Length

Q1. What affects bond strength?

A: Bar type, concrete grade, cover, placement quality, and curing.

Q2. Which bond is strongest?

A: Mechanical bond with TMT bars.

Q3. Is development length same for tension and compression?

A: No. It is reduced by a factor of 1.25 in compression.

Q4. What happens if Ld is insufficient?

A: It can cause slippage, cracks, and structural failure.

💡 PYQs on Bond and Development Length (JKSSB/SSC)

Q1. Development length of a bar depends upon:

a) Diameter of bar

b) Bond stress

c) Grade of steel

d) All of the above

✅ Ans: d) All of the above

Q2. Development length of a 12 mm bar in tension in M20 concrete is:

a) 648 mm

b) 1000 mm

c) 1045 mm

d) 870 mm

✅ Ans: a) 648 mm

Q3. Which IS code specifies design bond stress?

✅ Ans: IS 456:2000

📅 Conclusion

The concepts of bond and development length are foundational in Reinforced Cement Concrete (RCC) design. Bond ensures that tensile forces in steel are effectively transferred to concrete, allowing the two materials to act as a single structural unit. Without adequate bonding, the integrity of RCC elements such as beams, slabs, and columns is severely compromised, leading to premature failures such as cracking or slippage.

The development length (Ld), derived from IS 456:2000 guidelines, is the minimum embedded length required to fully develop the strength of a reinforcement bar. This becomes particularly crucial at supports, lap joints, and anchorage points, where the stress transfer is at its peak. An accurate understanding of Ld helps engineers ensure structural safety without unnecessarily increasing bar lengths, thus achieving both economy and strength.

In practical site conditions, factors like improper compaction, poor cover, incorrect bar placement, or inferior concrete can affect bond performance. Therefore, a good civil engineer not only applies the formulas but also ensures quality workmanship and proper detailing at junctions, bends, and terminations.

From an exam perspective (like JKSSB JE Civil), this topic is frequently covered through both conceptual questions and numerical problems. Memorizing standard values (like design bond stresses), formulas, and hook/bend lengths gives candidates a solid edge in competitive exams.

In conclusion, mastering this topic is not only essential for cracking civil exams but also for becoming a competent and safety-conscious structural engineer.

📌 Join our Telegram Channel JKSSB CivilsCentral for regular updates, quizzes, PDF notes, and practice sets curated specifically for JKSSB aspirants.