🗕️ Updated on: August 2025

📘 Introduction

Mix Design is one of the most crucial aspects of Concrete Technology, forming the foundation for producing concrete with consistent quality and performance. It is defined as the systematic process of selecting suitable ingredients (cement, fine and coarse aggregates, water, and admixtures) and determining their appropriate proportions to achieve desired properties such as strength, workability, and durability, at the most economical cost.

Proper mix design ensures that the concrete performs as expected under various environmental and loading conditions, minimizing material wastage and improving sustainability. It incorporates both theoretical knowledge and practical laboratory trials, guided by standards like IS 10262:2019 and IS 456:2000.

This topic is frequently covered in JKSSB JE Civil, SSC JE, and various other state-level engineering exams. A clear understanding helps aspirants solve conceptual as well as numerical questions efficiently. Let’s explore the concept in depth with technical insights, code references, and practical applications.

📌 What is Mix Design?

Mix design is the scientific and engineering-based process of determining the optimum proportions of ingredients—cement, fine aggregates (sand), coarse aggregates (gravel or crushed stone), water, and optional admixtures—to achieve the desired mechanical and durability characteristics of concrete in both its fresh (plastic) state and hardened (solidified) state.

This process involves not just calculating theoretical ratios but also conducting laboratory trials to verify workability (e.g., slump), strength (7-day and 28-day compressive strength), and durability (resistance to chemical attack, shrinkage, etc.). A well-designed mix ensures the concrete is easy to handle and place, strong enough to carry loads, and durable for the expected service life, all while being cost-effective and environment-friendly.

🧱 Main Objectives:

- Achieve target strength: This refers to designing the concrete mix so that it consistently meets or exceeds the required characteristic compressive strength (e.g., 25 MPa for M25) at 28 days. The target strength is calculated by adding a margin (based on standard deviation) to account for variations in material properties and construction practices.

- Ensure workability for placing and compaction: Workability refers to the ease with which concrete can be mixed, transported, placed, and compacted without segregation or bleeding. A workable mix ensures proper compaction, which leads to better strength and durability. It is influenced by water content, aggregate shape and size, admixtures, and the overall mix proportions. Workability is commonly measured using the slump test, with different structural elements requiring different slump values (e.g., 25–75 mm for footings, 75–100 mm for slabs and beams). Lack of workability may lead to honeycombing, segregation, or improper compaction, which compromises the structural integrity.

- Guarantee durability for expected service life: Durability refers to the ability of concrete to resist weathering action, chemical attack, abrasion, and other deterioration processes throughout its service life. A durable concrete mix ensures that structures can maintain their functionality and safety under various environmental conditions (e.g., sulfate attack, freeze-thaw cycles, chloride exposure). Factors such as low water-cement ratio, adequate cement content, proper curing, and the use of supplementary cementitious materials (like fly ash or silica fume) significantly improve durability. Durable concrete reduces long-term repair costs and ensures serviceability in aggressive environments like coastal areas or industrial zones.

- Optimize cost efficiency: Mix design aims to minimize the overall cost of concrete production without compromising quality. It achieves this by reducing cement content (which is the most expensive component), optimizing the use of locally available materials, and avoiding unnecessary use of admixtures. A well-designed economical mix ensures material efficiency and sustainability by reducing CO₂ emissions and energy consumption in cement production.

🧪 Types of Concrete Mixes

| Type | Description | Example |

|---|---|---|

| Nominal Mix | Prescribed ratio by volume | 1:2:4 (M15) |

| Standard Mix | Prescribed grade as per IS | M20 |

| Design Mix | Based on lab trials & material properties | M25 and above |

✅ Design Mix Concrete is preferred in large and important projects as it is more economical and performance-based.

📏 Mix Design as per IS 10262:2019

IS 10262:2019 is the code of practice for concrete mix proportioning in India.

🔹 Steps in Mix Design (Simplified):

The concrete mix design process involves a sequence of logical steps that ensure the final concrete mix meets strength, workability, durability, and economy requirements. As per IS 10262:2019, the standard method involves the following steps:

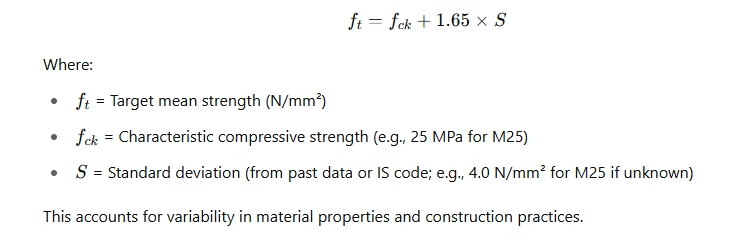

1️⃣ Determine Target Mean Strength

To ensure the mix consistently meets the characteristic compressive strength (fₖ), we calculate the target mean strength (fₜ)

2️⃣ Selection of Water-Cement Ratio (W/C Ratio)

- Choose w/c ratio based on durability requirements from IS 456:2000.

- Ensure that the selected value also satisfies strength requirements from trial mixes or strength graphs.

Typical limits:

Lower w/c ratio improves strength and durability but reduces workability.

3️⃣ Selection of Water Content

- Water content influences workability.

- Approximate water content is chosen from IS 10262 tables based on:

- Aggregate size

- Desired slump

- Use of admixtures

For example:

- For 20 mm aggregate and 50–75 mm slump → water ≈ 186 kg/m³

🧪 Use of plasticizers allows reduction in water content by 5–20% without reducing workability.

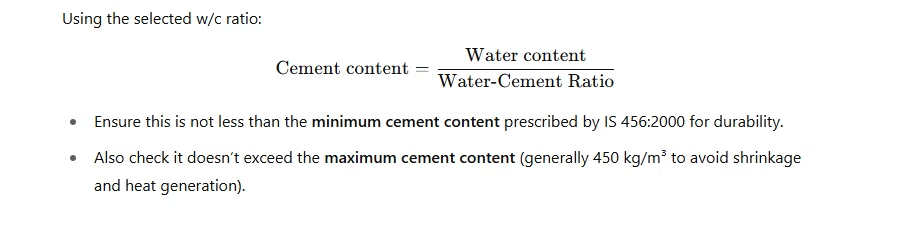

4️⃣ Calculation of Cement Content

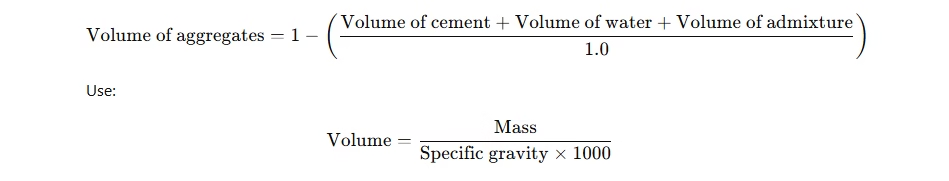

5️⃣ Proportioning of Aggregates

- Based on the maximum aggregate size, zone of sand, and type of aggregate (angular/rounded).

- IS 10262 provides tables to decide the percentage of coarse and fine aggregate in the total aggregate content.

For example:

- For 20 mm coarse aggregate and Zone II sand → fine aggregate ≈ 35%

6️⃣ Adjustment for Moisture Content

- Aggregates carry moisture or absorb water, which affects the water-cement ratio.

- Adjust water and aggregate content to account for:

- Free surface moisture in aggregates (adds water to mix)

- Water absorption by dry aggregates (reduces water from mix)

Corrected water content=Selected water±Moisture adjustment\text{Corrected water content} = \text{Selected water} \pm \text{Moisture adjustment}Corrected water content=Selected water±Moisture adjustment

7️⃣ Trial Mixes and Testing

- Prepare at least 3 trial mixes using different aggregate/cement ratios.

- Test for:

- Workability (Slump test)

- Strength (7 and 28-day compressive tests)

- Durability indicators (if required)

Finalize the mix that gives required workability, strength, and economy.

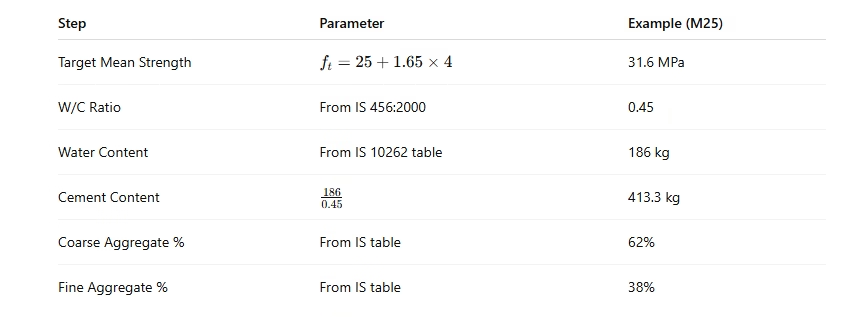

✅ Sample Summary Table (Example for M25 Mix)

📊 Example: Mix Design for M25 Grade

| Parameter | Value |

|---|---|

| Target strength | 31.6 MPa |

| Water-cement ratio | 0.45 |

| Water content | 186 kg |

| Cement content | 186 / 0.45 = 413.33 kg |

| Fine Aggregate | 650 kg (approx.) |

| Coarse Aggregate | 1200 kg (approx.) |

🔍 These values vary based on local material properties, and lab trials must be conducted for accuracy.

📆 Factors Affecting Mix Design

Understanding the factors that affect mix design is crucial to ensure the desired performance of concrete under different site and environmental conditions. These factors influence the selection of materials, proportions, and properties of both fresh and hardened concrete.

1. 🧱 Type of Cement

The type and grade of cement used significantly affect the mix design:

- Ordinary Portland Cement (OPC) offers higher early strength, making it suitable for precast works or urgent construction timelines.

- Portland Pozzolana Cement (PPC) improves durability and is preferred in aggressive environments (e.g., sulfate-prone or marine areas).

- Rapid Hardening Cement increases early strength but generates more heat.

- Low Heat Cement is ideal for mass concreting like dams to reduce thermal cracks.

Each type influences setting time, strength gain, heat of hydration, and final strength of concrete.

2. 🪨 Aggregate Size and Shape

- Size of Aggregate affects workability and strength. Larger aggregates reduce the water demand but may affect uniformity in heavily reinforced sections.

- Shape of Aggregate (rounded vs angular):

- Rounded aggregates (like river gravel) improve workability and reduce water demand.

- Angular aggregates (like crushed stone) increase interlocking and strength but reduce workability.

- Grading of aggregates ensures good packing and reduced voids, which improves strength and reduces cement consumption.

📝 IS 383:2016 provides specifications for aggregate grading and quality.

3. 🧪 Required Slump/Workability

Workability refers to the ease of placing, compacting, and finishing concrete.

- High workability is required for pumped concrete, columns, or areas with dense reinforcement.

- Lower workability is acceptable in unreinforced or mass concrete.

- Water content, use of admixtures, and aggregate shape/size directly impact slump.

Typical slump values:

- Footings: 25–75 mm

- Beams/slabs: 75–100 mm

- Columns: 100–150 mm

Use of plasticizers or superplasticizers improves workability without increasing water content.

4. 🌧️ Exposure Conditions

The environmental exposure plays a key role in defining the minimum cement content, maximum water-cement ratio, and cover requirements, as per IS 456:2000.

| Exposure | Example | Max W/C Ratio | Min Cement (kg/m³) |

|---|---|---|---|

| Mild | Indoor dry environment | 0.60 | 300 |

| Moderate | Outdoor without harsh weather | 0.50 | 300 |

| Severe | Marine/industrial areas | 0.45 | 320 |

| Very Severe | Near sea coasts | 0.45 | 340 |

| Extreme | Direct seawater contact | 0.40 | 360 |

Proper mix design helps concrete withstand sulfate attack, freeze-thaw cycles, chloride ingress, etc.

5. 💧 Curing Conditions

Curing maintains moisture and temperature after concrete is placed, ensuring proper hydration of cement.

- Poor curing leads to reduced strength and durability.

- The mix should be designed keeping in mind whether curing will be continuous (e.g., with water), intermittent, or by curing compounds.

- In hot climates, water-retaining admixtures and low w/c ratio mixes are preferred.

6. 🧪 Use of Admixtures

Admixtures are added to enhance specific properties of concrete. Their use directly impacts mix design proportions:

- Plasticizers/Superplasticizers: Improve workability at low water content.

- Accelerators: Speed up setting time (useful in cold weather).

- Retarders: Delay setting time (useful in hot climates or long transport).

- Air-Entraining Agents: Improve freeze-thaw resistance.

- Mineral Admixtures: Like Fly Ash, Silica Fume, and GGBS are used for enhanced strength and durability.

The dosage of admixtures must be carefully calibrated as per manufacturer guidelines and verified through lab trials.

✍️ Why Mix Design Matters in Exams like JKSSB?

- Direct questions are asked from IS 10262 and mix types.

- MCQs based on nominal mix ratios, grade of concrete, and w/c ratio limits are common.

- Understanding mix design helps in solving questions from topics like durability, workability, and strength of concrete.

❓ FAQs on Mix Design

Q1. What is the water-cement ratio for M20 as per IS code?

✅ Generally around 0.5, but depends on exposure conditions.

Q2. Which IS code is used for mix design?

✅ IS 10262:2019

Q3. What is the difference between nominal mix and design mix?

✅ Nominal mix uses fixed ratios; design mix is based on lab tests.

Q4. What is target mean strength?

✅ It is higher than characteristic strength to account for variations in material and workmanship.

📚 Previous Year Questions (PYQs) – JKSSB/SSC JE

Q. IS Code for Concrete Mix Design?

a) IS 383

b) IS 456

c) IS 10262 ✔️

d) IS 2386

Q. Nominal Mix Ratio for M20?

a) 1:1.5:3 ✔️

b) 1:2:4

c) 1:1:2

d) 1:3:6

✅ Conclusion

Concrete mix design is the backbone of quality concrete construction. For JKSSB Civil Engineering aspirants, understanding the principles of mix proportioning, IS code guidelines, and mix types is essential to score well in exams.

This topic connects to several others like strength of concrete, durability, and workability, making it a high-value subject in your preparation.

📌 Join our Telegram Channel JKSSB CivilsCentral for regular updates, quizzes, PDF notes, and practice sets curated specifically for JKSSB aspirants.